In the field of management, there are various approaches that principally aim to accelerate and boost corporate firms’ revenues and operational efficiencies.

In the field of management, there are various approaches that principally aim to accelerate and boost corporate firms’ revenues and operational efficiencies.

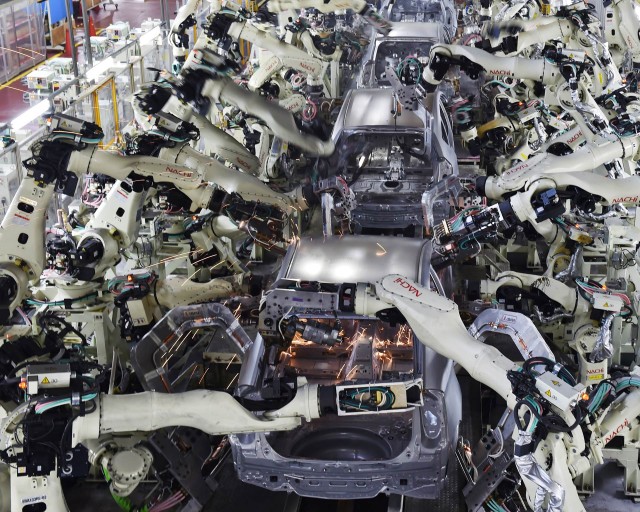

Progressive companies from around the world have been coming up with different strategies for corporate improvement. Some of these schemes have been so effective that other firms have recognized and even adopted them. One of these efficiency-focused philosophies is what is termed ‘lean manufacturing.’

What is lean manufacturing?

Lean manufacturing is a holistic and strategic approach that aims to enable businesses and companies to improve and boost competitiveness and profitability. Leaning–at least in part these days on IoT and Artificial intelligence, lean manufacturing aims to set in desired improvements through identification and elimination of wasteful or unproductive behavior and practices among employees and management.

Lean manufacturing is a program or methodology that could prove to be fitting and appropriate for all types of businesses or organizations. Lean manufacturing would be effective whether adopted by companies in the manufacturing, service, trading or other sectors.

Lean manufacturing is focused at helping companies get the right things, to the right and appropriate places, at the perfect or right time and in the right amount or quantity while at the same time, reducing waste and promoting productivity and flexibility among workers.

Lean manufacturing and waste

It does not take a successful manager to assert that businesses and companies carry unnecessary and unlikely burden of wastes.

Lean manufacturing as a philosophy focuses on reducing the seven wastes commonly identified among global firms. Lean manufacturing attempts to help companies eliminate these unnecessary wastes to improve output quality, to maximize production and the time needed for it and mostly, to significantly save on costs.

The seven wastes lean manufacturing aims to slash and eliminate in the workplace are the following:

- Over production

- Over processing

- Transportation

- Motion

- Inventory

- Waiting

- Scrap and defects

Over production, over processing and inventory

While some companies view over production in the positive way, most, especially those in the service and manufacturing sectors, take it as a manufacturing liability.

Over production will create a piling of inventory that would eventually create a problem in distribution because most warehouses have capacity limits.

What is worse is that over production and piling of inventories are the usual causes of price drops, which are deemed bad for the business by most firms.

The fundamental law of supply and demand will attest that if supplies are exceeding or too much, then demand tries to settle down or decline. Demands going down will mean prices rolling back or dropping as well.

Over production is unnecessary because it takes away productive time from employees and managers. There are many disadvantage of over processing and most of them seem pretty obvious to you. Over processing increases cost.

Transportation, motion and waiting

Because time is an important element of productivity, lean manufacturing values it the most. Thus, lean manufacturing philosophy aims to boost efficiency.

Transportation is an essential element of manufacturing because through it commodities and merchandise are distributed to retailers, down to the consumers.

However, lean manufacturing mandates that firms maximize the use of transportation especially nowadays when oil prices are high.

Because energy prices are rising, and energy is what keeps companies rolling, motion should be controlled. Lean manufacturing will have companies slash procrastination and unproductive hours among employees so as to increase and meet sufficient production targets.

If motion is made efficient, then waiting could be reduced if not eliminated. In lean manufacturing, waiting makes people idle and it kills time that should have been used in more productive endeavors and activities.

Scrap and defects

Lean manufacturing have it that if employees are efficient and if they are motivated, the quality of production would be greatly boosted. That means, the company will not have to spend costs on wages, energies and other capital just to produce defective items that would eventually be rejected upon distribution.

While scraps and defects in production items are inevitable, companies adhering to lean manufacturing principles could always do something about it. Basic management principles have it that motivation is the most effective incentive to get workers doing the right and proper procedures in the work place.

All the seven wastes that are targeted by lean manufacturing strategies are interconnected with the elimination of one leading to the elimination of the others.